Clear zinc plating, which is more commonly referred to as zinc electroplating, is considered one of the most popular, and widely used, finishes for a number of industries. There are a number of reasons for this, with the primary one being that this is a cost-effective process. This option is used to provide a protective coating to various metallic substances, including automotive parts, bolts, fabrications, brackets, nuts, precision, as well as a number of other types of sheet metal.

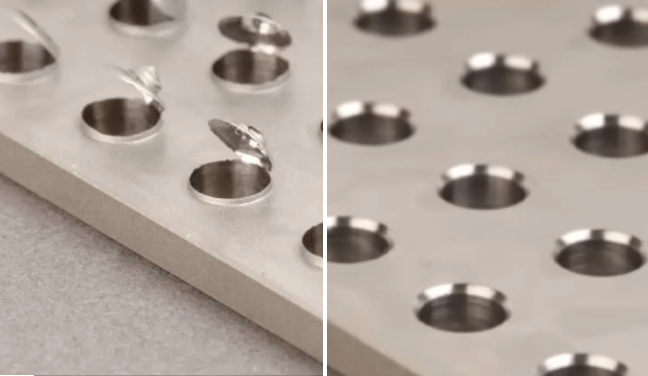

In additional to these benefits, zinc will also improve the entire appearance of various metals by providing them with a clean, bright shine.

Clear Zinc Plating Advantages

The primary adv antages of clear zinc plating include the simplicity of the application process and the fact that it is extremely affordable. It is also a popular substance that is used for paint undercoating, since it will prevent white rust formation for a long time period and provides superior adhesive and ductile properties.

While clear zinc plating is, by far, the most popular option, there is also a way to increase the visual aesthetics by using yellow iridescent or yellow zinc plating. There are also silver zinc plating and olive green, as well as black zinc plating options.

The zinc coating is able to be post-treated by using lacquers, as well as different types of silicate seals that will help to enhance the corrosion value or to improve the handling properties.

Zinc Electroplating Passivation

There are four different passivation systems that are used as a type of top coat treatment that will work to delay the appearance of whit corrosion. These include black, olive, yellow and clear. Generally speaking, yellow and clear zinc plating is used most often due to the aesthetics and the service condition requirements.

When clean plating is controlled properly, it will provide a bright finish that shoes a blue to silver tint, while yellow will appear either gold or yellow with green and red iridescence. The colors can vary due to the temperature conditions during application, as well as a number of other factors.

In most cases, clear passivation will be used for the internal components, such as electronic metal fabrications and a number of fasteners. Yellow is typically used for external parts, which might be subject to damp, wed and even salt exposure conditions. This is most commonly seen with motor vehicles and agriculture machinery.

Determining the best option for your parts and metal needs will mean that you need to look at how the equipment is being used. Clear zinc plating is extremely popular and something that is seen across all industries, making it one of the most commonly used options.