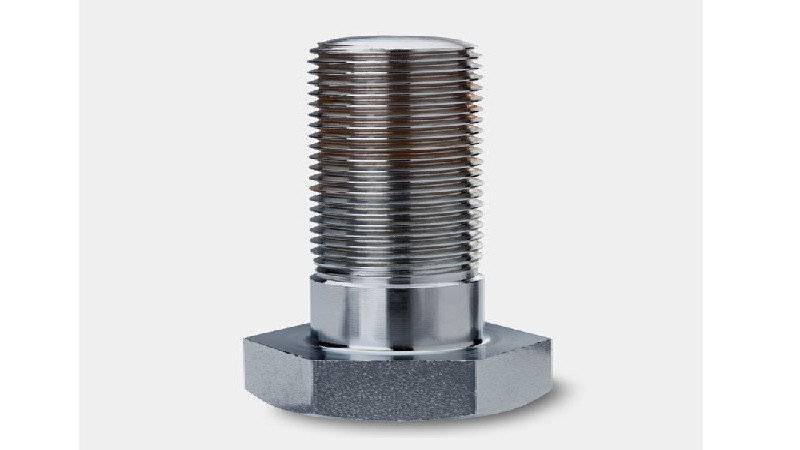

Using stainless steel threaded fasteners has become extremely popular due to their recyclable and corrosion resistant properties. They can offer resistance against any usage level and offer superior load-bearing capabilities in both cold and hot weather. However, if you don’t handle the fasteners properly, they may become damaged. Some mistakes you should try to avoid are found here.

Selecting the Wrong Grade

An important factor to keep in mind when using stainless steel threaded fasteners is the grading of the steel. The two most commonly used grades are 304 and 316. That is because they offer better corrosion resistance than the other options available. If the fastener is going to be used in an environment that’s extremely susceptible to corrosion, using 316 stainless steel is best.

Contaminating the Exposed Surface

The part of the metal that is exposed to the atmosphere may be contaminated by metallic dust. This can eventually result in the formation of rust on the surface of the threaded fasteners you used. As time passes, this will gradually decay the material from the inside.

Choosing Low-Nickel Stainless Steel

It has been proven that the 200 series stainless steel fasteners are deficient in chromium. This means that the combination of metals present are not suitable to resist rusting compared to what is offered by 316 stainless steel.

Ineffective Cleaning Schedules

The lifespan of a stainless steel fasteners is dependent on the cleaning schedule for the equipment it is used on. If the contaminates are allowed to settle for extended periods of time, it may be difficult to clean the particles away. The appearance of the steel may also be distorted.

When you learn about the most common mistakes that lead to issues with fasteners, you can be sure to avoid them. When you do this, it will help to extend the longevity of the item in question.