In today’s competitive manufacturing landscape, American industries are under constant pressure to boost productivity while reducing operational costs and environmental impact. One of the most effective ways to achieve these goals is by improving energy efficiency within industrial processes. A key technology supporting these improvements is the Plate Type Heat Exchanger, a device that has transformed the way manufacturers manage heating and cooling across various applications.

Understanding Plate Type Heat Exchangers

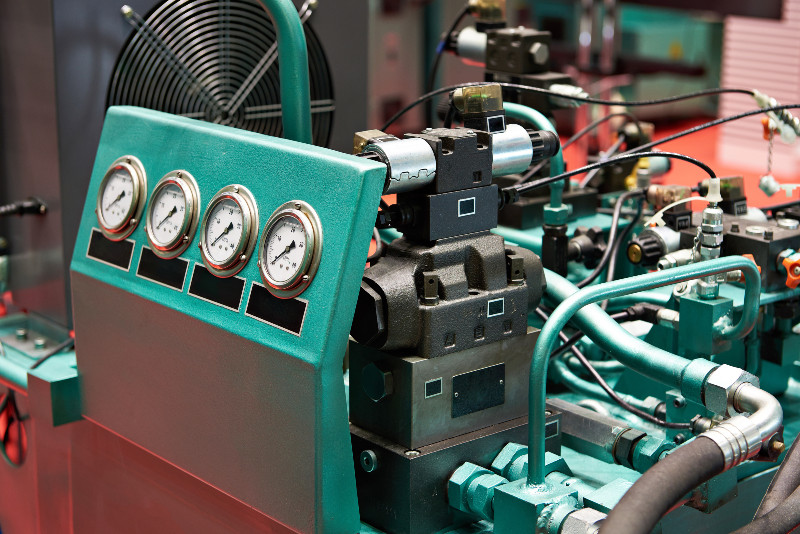

A plate type heat exchanger is designed to transfer heat between two fluids without mixing them. It consists of multiple thin, corrugated metal plates stacked together, creating a series of parallel channels for fluid flow. The unique design offers a large surface area for heat transfer, allowing for efficient exchange of thermal energy. This innovative approach is particularly well-suited for American manufacturing environments, where process optimization is crucial.

Energy Efficiency Advantages in Manufacturing

The adoption of plate type heat exchangers in American factories brings several distinct benefits:

1. Superior Heat Transfer Efficiency

- Maximum Surface Area: The extensive plate surface area promotes rapid heat exchange, minimizing energy loss.

- Thin Plate Construction: The thinness of the plates enables quick temperature changes, which reduces the time and energy needed to reach desired process conditions.

2. Compact Design and Flexibility

- Space-Saving Footprint: Unlike traditional shell-and-tube heat exchangers, plate models require less floor space, making them ideal for facilities with limited room.

- Modular Construction: Manufacturers can easily expand capacity or adjust configurations as production needs change, ensuring long-term adaptability.

3. Reduced Operating Costs

- Lower Energy Consumption: Improved heat transfer efficiency means less energy is required for heating or cooling, directly reducing utility bills.

- Minimal Maintenance: The easy-to-clean design and fewer moving parts lead to lower maintenance costs and less downtime.

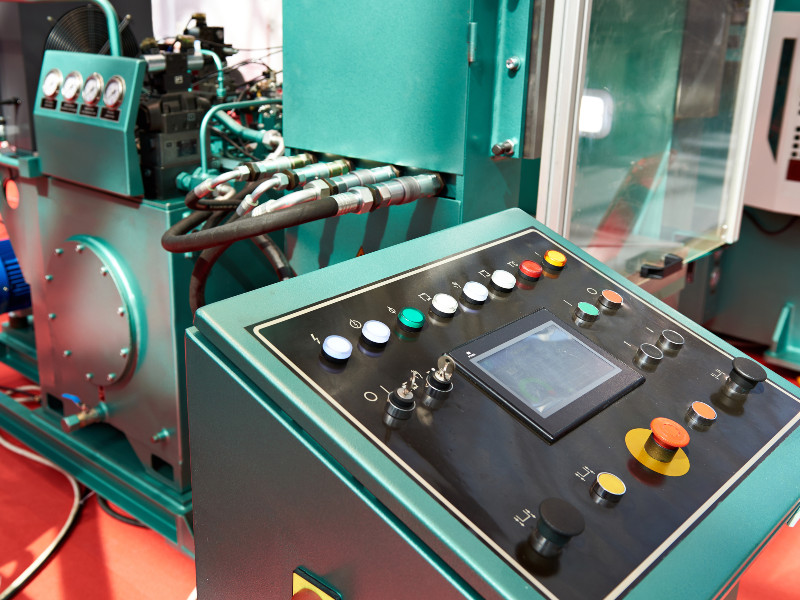

4. Enhanced Process Control

- Precise Temperature Regulation: Plate type heat exchangers allow for accurate control of process temperatures, ensuring product quality and consistent output.

- Quick Response to Load Changes: The system’s design enables rapid adjustments to fluctuations in production, supporting flexible manufacturing operations.

Applications Across American Manufacturing Sectors

Plate type heat exchangers are used in a wide range of manufacturing industries, including:

- Food and Beverage: For pasteurization, sterilization, and cooling of products.

- Chemical Processing: For temperature control in reactors and mixing tanks.

- Pharmaceuticals: For maintaining strict temperature requirements during production.

- HVAC Systems: For efficient climate control in large manufacturing facilities.

Their versatility makes them a preferred choice for manufacturers seeking to improve energy efficiency without sacrificing performance or reliability.

Key Considerations for Implementation

To maximize the benefits of a plate type heat exchanger, manufacturers should:

- Assess Process Requirements: Evaluate flow rates, temperature ranges, and compatibility with process fluids.

- Prioritize Regular Maintenance: Implement a cleaning and inspection schedule to maintain peak efficiency.

- Invest in Quality Materials: Choose plates and gaskets that resist corrosion and fouling, extending equipment lifespan.

By following these best practices, American manufacturers can ensure their heat exchangers deliver optimal performance and energy savings over the long term.

Driving Sustainable Growth Through Energy Efficiency

Embracing advanced technologies like plate type heat exchangers is essential for American manufacturers looking to enhance energy efficiency, reduce costs, and remain competitive. The combination of superior heat transfer, compact design, and operational flexibility makes this equipment a smart investment for diverse industries. By integrating these systems into their processes, manufacturers can achieve significant energy savings, support sustainability goals, and drive long-term growth in a rapidly evolving market.