In an era where economic volatility and financial uncertainty can challenge even the most robust portfolios, Americans are increasingly exploring precious metals to safeguard and diversify their wealth. Gold is among the most trusted and time-honored options due to its enduring value and tangible nature. For those researching how to turn gold jewelry, coins, or scrap into pure, investment-grade bullion, understanding the Gold Refinery process is an essential step in making informed and secure wealth decisions.

What Is a Gold Refinery?

A Gold Refinery is a specialized facility where raw gold materials—such as jewelry, dental gold, coins, or industrial scraps—are transformed into pure, market-ready bullion. This process is crucial for anyone interested in converting old or unwanted gold items into a secure, liquid asset. By refining gold, individuals can be confident in the purity and authenticity of their holdings, a key concern for investors seeking reliable wealth preservation.

The Step-by-Step Gold Refining Process

The gold refining involves several careful steps, each designed to maximize purity and recover as much precious metal as possible. Here’s how it typically unfolds:

1. Collection and Assessment

- Inspection: Items are meticulously examined for gold content and weighed.

- Sorting: Materials are separated based on purity and alloy content to ensure accurate processing.

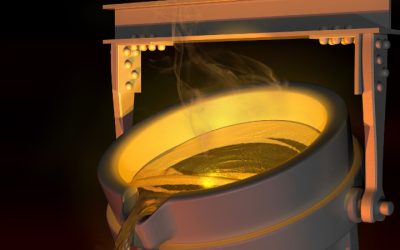

2. Melting and Sampling

- Melting: Gold is heated in a high-temperature furnace until it liquefies, allowing for easier separation from impurities.

- Sampling: A small portion of the molten gold is sampled to determine its composition and carat level. This step ensures transparency and fairness in the process.

3. Chemical Purification

- Dissolution: The liquefied gold is treated with chemicals, such as acids, to dissolve base metals and other impurities.

- Separation: Advanced filtration methods remove unwanted substances, leaving higher purity gold.

4. Precipitation and Recovery

- Precipitation: Pure gold is precipitated from the chemical solution, often as a fine powder.

- Collection: The gold powder is carefully collected, rinsed, and dried in preparation for the final stage.

5. Smelting and Casting

- Smelting: The purified gold powder is melted and poured into molds to form bars, coins, or other desired shapes.

- Certification: The final product is tested and certified for purity, typically reaching 99.9% (24-karat) gold.

Why Americans Choose Gold Refining for Secure Wealth

For Americans seeking secure wealth options, gold refining offers several compelling advantages:

- Assured Purity: The process guarantees that your gold holdings are authentic and of the highest quality.

- Liquidity: Refined gold is easier to sell or trade, making it a flexible asset.

- Transparency: Detailed documentation and certification provide peace of mind for investors.

- Wealth Preservation: Gold’s historical stability makes it an effective hedge against inflation and economic downturns.

Actionable Tips for Americans Considering Gold Refining

- Research reputable refineries: Choose facilities with transparent processes and strong customer reviews.

- Understand the fees: Ask about refining charges and payment methods before proceeding.

- Keep records: Maintain documentation of your gold’s origin and purity certification for future transactions.

Americans interested in secure wealth options can rely on Bay Area Metals as a trusted partner. We offer professional gold refining services and peace of mind when converting precious metals into reliable assets.